Smart Manufacturing for Automotive

-

Enabling the Acceleration of Factory Conversion to Smart Factories

RTInsights talks with Siemens about the need to convert to smart factories, the technologies that can help, and the benefits that automakers can derive from making the change.

Read more -

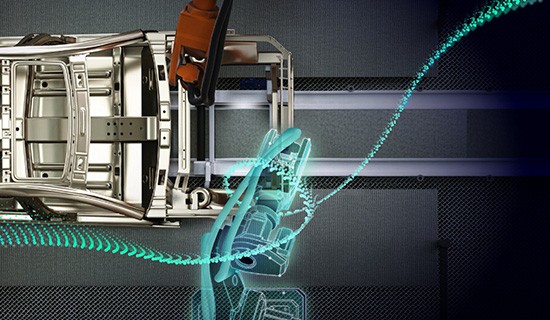

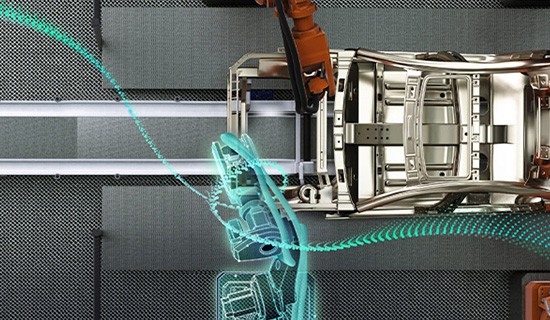

Human-robot Collaboration and Smart Manufacturing

Virtual commissioning and digital twins can help automakers and their Tier 1 parts suppliers ensure that their human-robot collaboration projects achieve their desire objectives without posing a safety threat to the human operators.

Read Now -

Addressing a Fact of Life: Compressed Development and Launch Times in Auto Manufacturing

Automakers can successfully address compressed development and launch timelines by embracing Agile methodologies, advanced digital tools, and flexible supply chain strategies.

Read more

Trending Now

Smart manufacturing for automotive and transportation

Drive operational excellence with intelligent technologies and advanced automation Navigate rapid change and achieve operational excellence by embracing smart manufacturing for next-level automation, and production excellence.

The value of smart manufacturing in automotive

Modernize your operations with advanced manufacturing solutions for consistent, on-time delivery of high-quality products. Integrate and optimize plant processes, people, and next-level automation to achieve flexibility, efficiency, and sustainability.

Resources

Enabling the Acceleration of Factory Conversion to Smart Factories

RTInsights talks with Siemens about the need to convert to smart factories, the technologies that can help, and the benefits that automakers can derive from making the change.

Human-robot Collaboration and Smart Manufacturing

Virtual commissioning and digital twins can help automakers and their Tier 1 parts suppliers ensure that their human-robot collaboration projects achieve their desire objectives without posing a safety threat to the human operators.

Addressing a Fact of Life: Compressed Development and Launch Times in Auto Manufacturing

Automakers can successfully address compressed development and launch timelines by embracing Agile methodologies, advanced digital tools, and flexible supply chain strategies.

2024 Automotive Smart Manufacturing Trends

There is no question that auto manufacturers will rely on smart manufacturing strategies and solutions in the coming year. Here are some trends to look for in 2024.

A Deep Dive into Virtual Commissioning

Virtual commissioning uses digital twins, sophisticated simulations, and modeling to help manufacturers adjust to changes and modernize their operations.

Why Auto Makers Must Move to Intelligent Manufacturing Operations

A discussion about the factors driving the need for smart manufacturing, key technologies that help auto manufacturers make that change, and the benefits they will realize in using the technologies and solutions.

Accelerating Innovation: How Virtual Development Mitigates Rapid Change in Auto Manufacturing

Virtual development is a tool for innovation and efficiency and will continue to be a cornerstone in the evolution of auto manufacturing, shaping the vehicles of tomorrow and the processes that create them.

What’s Next for Smart Factories? A Look Ahead to Industry 5.0

Industry 5.0 builds on the technologies of Industry 4.0 but emphasizes sustainability and the collaboration between humans and machines.

Enabling Greatly Needed Flexibility with Smart Manufacturing

While most associate smart manufacturing with improvements in operational efficiencies and faster time to market, the same principles and solutions deliver the flexibility to adapt to market changes.

Building a More Sustainable Factory Floor Leveraging Smart Manufacturing

Auto manufacturers are adopting smart manufacturing strategies to modernize facilities and improve the sustainability of their operations.

Not Your Father’s Auto Industry: Why Smart Manufacturing is Needed as We Head into 2024

Smart manufacturing technologies like digital twins, virtual commissioning, and more can bring about the required changes to move the industry forward in the years to come.

How Smart Technologies are Helping Simplify Sustainability in Auto Manufacturing

How Smart Technologies are Helping Simplify Sustainability in Auto Manufacturing

How Smart Manufacturing Makes Smart Autos Possible

Automakers are using virtual commissioning, digital twins, advanced supply chain management, and more to meet ever-changing customer demands for smart autos.

Smart Manufacturing Essential for the Transition to EVs

Many of the broad range of technologies (e.g., digital twins, virtualization, and more) that help auto manufacturers enable intelligent or smart manufacturing operations can play a role in the transition to EVs.

How AI-Driven Feedback Loops Make Car Manufacturing More Competitive

Integrating artificial intelligence (AI) into feedback-driven processes pushes the boundaries of what’s possible in automotive manufacturing.

Virtualizing the Automated Assembly Line

Automotive assembly line virtualization involves the use of digital tools and techniques to model, simulate, optimize, and manage assembly processes before they’re physically implemented.

Manufacturers Embrace Digital Twins for Enhanced Production

Manufacturers are looking into digital twins as a way to reduce the costs of commissions and improve client relations.

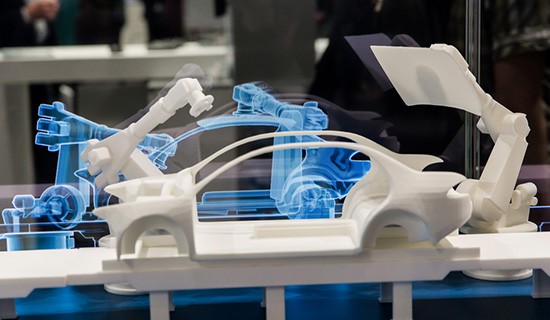

Enable virtual development to achieve smart manufacturing in automotive

By creating a digital twin of your production line, you can comprehensively evaluate machines, product lines, and plant designs early in the process. Allowing you to explore various scenarios before committing to a physical build, potentially saving significant costs.

Automotive quality management solution

Harness the power of data, monitor performance, and address operational issues in real-time. Transform your production facilities into intelligent plants with smart manufacturing solutions.

You Can’t Spell Smart Manufacturing Without AI

AI helps smart manufacturers use the vast amounts of data being generated from IoT devices and smart sensors throughout their factory.

Smart Factory Modernization Improves Efficiency

The automotive industry’s embrace of smart factory modernization will revolutionize production processes (and, in many cases, already has), enabling real-time monitoring, predictive maintenance, and optimized workflows.

IoT Connections To Grow by 400% In Four Years

IoT connections are expected to reach 142 million by 2027, primarily due to the growth in 5G standalone deployments.

Researchers Amplify Impact of Generative AI in Auto Design

A new technique allows designers to add engineering constraints into the text-to-image generative AI process, cutting down the iterations needed to address design considerations.

Smart Manufacturing: Melding Digital and Physical Worlds

Smart manufacturing helps automakers achieve greater efficiency and accelerate innovation by blending digital technologies with the physical realm, making it possible to accomplish things we’ve never seen before.

Digital Twins and Other Tech Enable Virtual Commissioning

Virtual commissioning saves time and money, and it avoids interruptions of existing work cells, production lines, and plants.

Why Automakers Need Intelligent Manufacturing Operations

Intelligent manufacturing solutions let companies react faster to issues on a production line or plant and to changing market conditions.

Rapid factory evolution for the automotive industry

Modernize your legacy equipment to drive outcomes with intelligent technologies.

Riding Out Automotive Market Uncertainty with Digital Twins

A critical aspect of using digital twins is that they can complement traditional forecasting and prescriptive tools by incorporating real-time monitoring and simulations.

Achieve a rapid plant evolution with Smart Manufacturing solutions

Discover how OEMs and suppliers can transform automotive production planning and processes with our Smart Manufacturing solutions for rapid factory evolution.

Digital Twins, IT/OT Convergence Drive the Industrial Internet

Digital twins offer a way to apply advanced analytics to derive insights that, in turn, drive optimization of production and operation processes.

Using Fuzzy Logic and AI to Improve Supply Chain Efficiency

The integration of fuzzy logic and AI presents significant opportunities for organizations like smart automotive manufacturers to enhance their supply chain management practices.

Manufacturing in a new automotive landscape

Technology advancements are transforming our means of transportation from into ever-more complex machines comprised of advanced software, electronics, and mechanical systems.

Drive sustainable, operational excellence with Siemens Smart Manufacturing

A powerful trifecta of advanced automation, intelligent solutions, and immersive technologies is defining the future of sustainable smarter manufacturing.

Drive quality and sustainability through intelligent production

Drive quality and sustainability through intelligent production While automotive manufacturers adopt IoT, AI, and machine learning, unlocking their full potential requires extracting actionable data insights for optimized production, reduced waste, and sustainability.